Automotive industry

Assembly of automotive components: exterior and interior components, electronic devices, as well as appearance and technical parts and much more... At teknics we are specialists in the production of special machines for assembly and functional testing. We have more than 30 years of experience in the demanding automotive industry.

Customers all over the world value the robustness of our flexible and process-oriented automation systems. Our innovative solutions are the most distinctive image of teknics.

Benefits

Customers from all over the world value the technical advantages of our production and test systems.

Detailed planning, industrial know-how, advanced technology, customized service: We offer highly flexible production systems for the assembly and monitoring of your products.

Turnkey solutions and customized machinery

Our customers’ requirements and needs are the starting point of our activity.

Once the technical requirements and the needs to be met have been analyzed, our team proposes the best solution, incorporating the latest technologies available on the market.

Cost-effectiveness and customization

The teknics production systems bring cost reduction for customers thanks to automation and optimization of processes.

The monitoring and verification solutions implemented in our machines, eliminate costs arising from a lack of quality.

Delivery reliability

In a sector where time to market gets shorter every day, teknics guarantees a speedy response and reliability in all processes.

Accuracy, trustworthiness and professionalism are characteristic features of our teams, which are focused on fulfilling the delivery times agreed with the customer.

Total quality commitment

Our highly qualified teams and the quality of our solutions mean that teknics can implement projects throughout the world. We guarantee the same compliance standards in Europe, Asia, Africa and America.

We make sure that every operation and collaboration with our suppliers complies with the same strict quality requirements.

No matter where you are, we provide reliable processes and proven systems to guarantee that your production system works from day one.

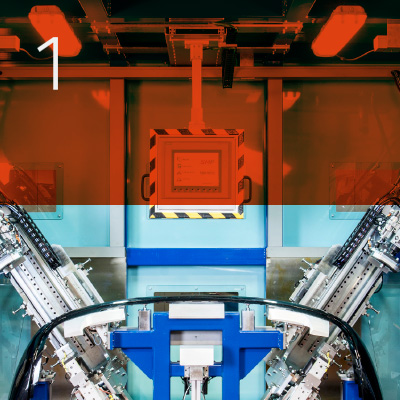

Assembly and testing

Integration of the latest applied technologies in production systems and quality testing.

Experts in products

teknics need to know your product. Together with our customers we carry out exhaustive feasibility studies of the future automation, anticipating contingencies and reducing the impact on production costs and timing.

Experts in processes

teknics has carried out more than 1,200 installations since 1992.

This experience is what helps us provide something more than a solution to a customer’s needs, offering a general vision of the project in a comprehensive way.

Assembly

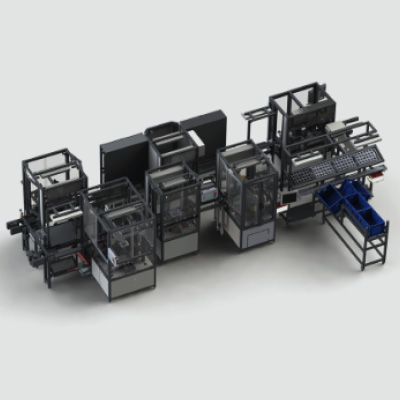

In collaboration with our customers we choose the best production solutions and the right type of automation of each process: FMS lines, rotary machines, semiautomatic machines, robotic stations, etc.

For every project we select the solution based on our experience and the technological developments generated by our innovation department.

Testing

At teknics, we are committed to technological innovation, incessantly seeking excellence in our testing solutions.

Each automation process requires different levels of control: traceability via CB or Data Matrix marking, RFID, automatic testing systems, serialization, OPC platforms, etc.

Each product requires different quality controls that guarantee our customers’ safety: from poka-yoke systems to advanced artificial vision monitoring systems, leakage checks, electronic functionality monitoring, calibration, etc.

Our aim is to provide control systems that is adapted to each process and each product, guaranteeing safety and better product quality for our customers.

Types

Turnkey and standard types of teknics machinery.

FMS: flexible

manufacturing system

Our FMS lines enable automation of production that varies a lot in terms of volumes as well as in terms of large number of product types and product characteristics.

These lines enable manual and automatic operations to be combined along the line, providing greater work flexibility. Furthermore, this type of line allows adaptation to our customers’ investment capacities, making it possible for the process to be automated gradually.

Máquinas

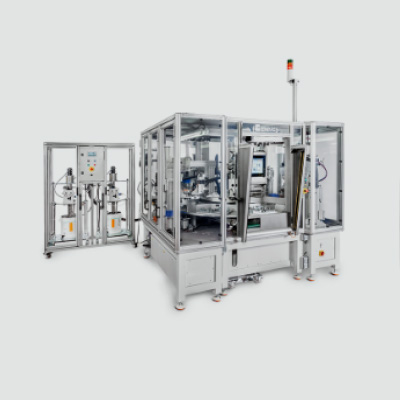

rotativas

Las máquinas rotativas realizadas por teknics están concebidas para la automatización de productos de tamaño reducido y con gran variedad de modelos.

El tiempo de ciclo puede ser inferior a 1 segundo por pieza. Alta producción con tiempos de ciclo muy estables.

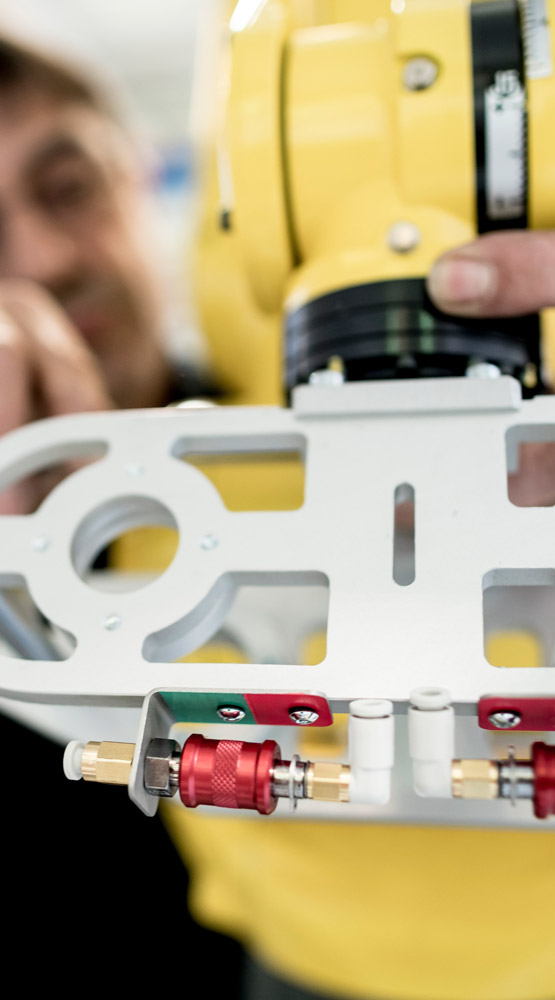

Estaciones

robotizadas

teknics diseña las células robotizadas de manipulación de componentes, integrando procesos de producción, testeo de producto y encajado automático.

Alta flexibilidad para cambio de formatos y versiones.

Puestos

semiautomáticos

En teknics cubrimos todas las necesidades de montaje de nuestros clientes incluso, aquellas aplicaciones que requieran un menor grado de automatización.

Operaciones de carga y descarga manual, así como operaciones de fabricaciones totalmente automatizadas, que permiten un elevado control sobre el producto.

Related projects

30 years and more than 1.200 projects carried out

-

Flexible feeding system with laser marking

Consisting of two synchronised robotic stations for artificial vision-guided loading and unloading of components. Station for laser marking and inspection of the engraved product. Speed: 4 seconds/part.

-

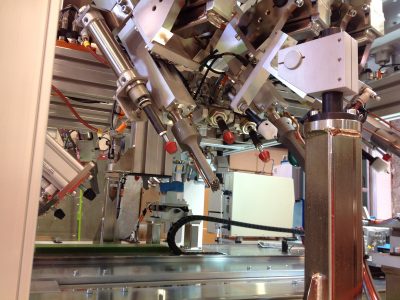

Rotary machine for assembling components

Rotary station with eight positions. This station includes applications such as: silicone dosing with volumetric control by a robot, electronic inspection and artificial vision, riveting with a hydraulic press and assembly of components. Speed: 18 seconds/part.

-

Semiautomatic machine for clipping components

It enables several components to be clipped at the same time. Composed of 57 rubberized push pieces with individual pneumatic regulation. Speed: 20 seconds plus manual loading and unloading by an operator.

-

Semiautomatic ultrasonic welding machine

Ultrasonic assembly and welding station with analog monitoring via four points for each deflector (right and left). Speed: 35 seconds/part.