Packaging automation

The teknics Packaging division was created with the aim of offering the best solution to the packaging sector.

The team of professionals that make up this division has extensive and proven experience in the packaging sector.

We offer solutions for the packaging of products in flowpacks, thermoforming machines, trays and cases, as well as the packing and palletising of all types of products.

Benefits

Our customers all over the world appreciate the benefits of teknics Packaging's flexible and adaptable solutions.

Detailed planning, intelligent technology, comprehensive service: Let us convince you of the benefits of teknics Packaging solutions.

Flexible and adaptable solutions

With the aim of providing flexible and adaptable solutions, our installations and packaging lines are designed with easy manoeuvrability criteria, simplifying format changes or automatic adaptation when the project requires it.

Hygiene and safety standards

Only with meticulousness and high standards we offer solutions for the food or pharmaceutical sector, guaranteeing compliance with the most rigorous hygiene and safety standards.

Reliable delivery times

In a sector where the time to market is getting shorter every day, teknics is committed to fast response times and the reliability of our lines.

The high demands of the food and pharmaceutical industry are one of our characteristic features.

Total quality commitment

teknics has extensive experience in selling its projects all over the world. Whether in China, the Czech Republic or South Africa, we guarantee the same high quality standards.

We require that every process and supplier in the world meets the same strict quality demands.

Products and solutions

Turnkey and standard types of teknics machinery.

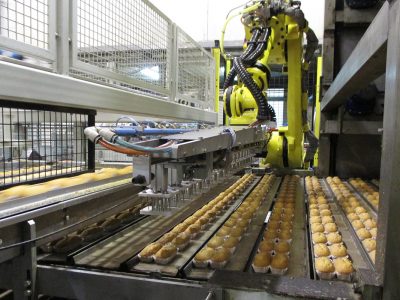

Automatic loading

Automatic loading by manipulators and robots for packaging machines which allows a high flexibility of products and formats.

• Flowpacks

• Thermoformers

• Trays

• Cartons

• Blisters

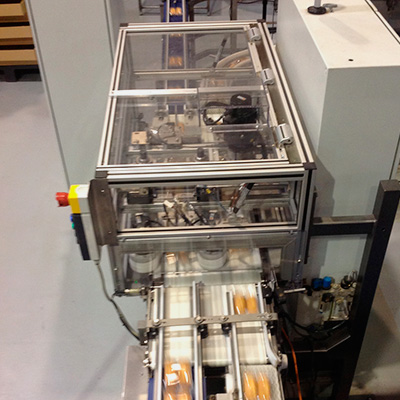

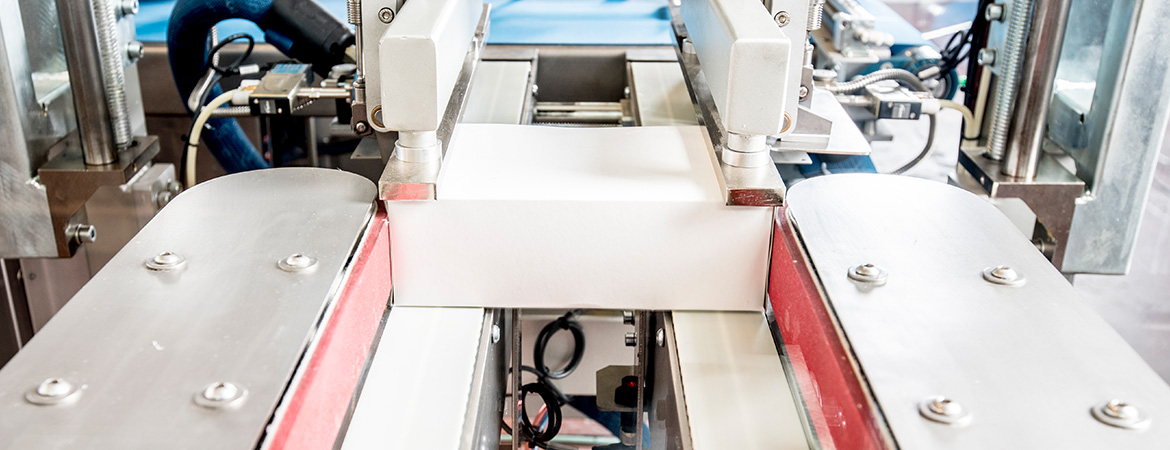

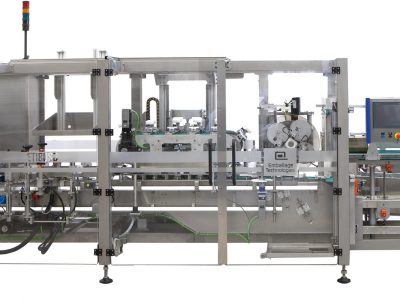

Cartoning and banding

Wide range of cartoning machines for diversified sectors as food, pharmaceuticals, cosmetics, etc.

• Compact cartoner

• Top loading

• Side loading

• Stretchwrapper

• Automatic loaders

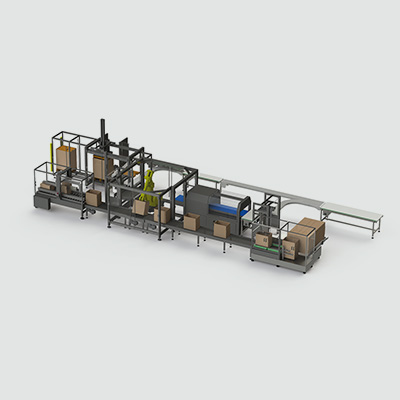

Case packing

Complete cartoning lines with various presentations and types of cartons. High flexibility in line design.

• Case erectors

• Automatic loading

• Case sealers

• Lid erector case erector

• Compact wrap-around case packing

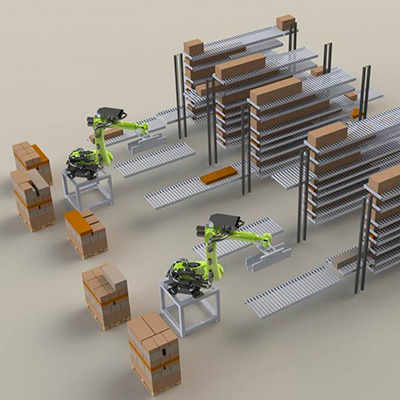

Flexible palletising

A system patented by teknics Packaging that allows the combination of different box formats and sizes on the same pallet to guarantee the formation of a stable pallet with maximum use of space.

Related projects

30 years and more than 1.200 projects carried out

-

Cartoner with automatic horizontal loading

Totally flexible, high-velocity machine. Adhesive system using hot-melt adhesive, with automatic switching. Carton dimensions: – Length: 75 a 320 mm – Width: 30-180 mm – Height: 16 to 100 mm Frequency: Up to 220 cartons/minute

-

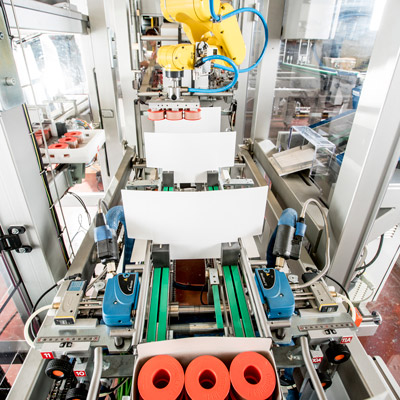

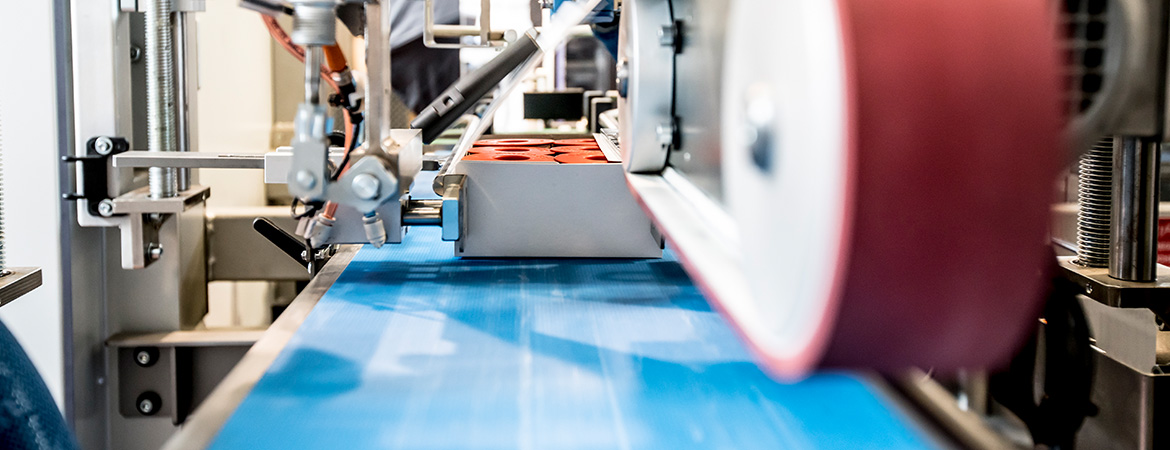

Robotized station loading onto flowpack line

Line that incorporates a robot for loading and unloading products (highly flexible) in flow pack for their later distribution and loading in multipack. Extendable gripper adapted to flow-pack pace. Rate: 280 packets/min.

-

Automatic palletizing

Robotic cell for the automatic palletizing of different box models. Rate: variable, depending on the box size.