Projects

-

Flexible feeding system with laser marking

Consisting of two synchronised robotic stations for artificial vision-guided loading and unloading of components. Station for laser marking and inspection of the engraved product. Speed: 4 seconds/part.

-

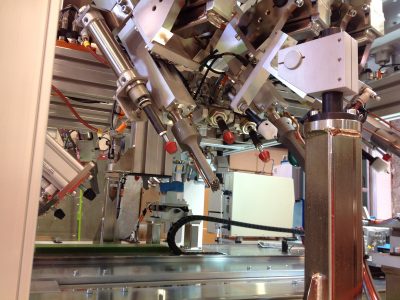

Rotary machine for assembling components

Rotary station with eight positions. This station includes applications such as: silicone dosing with volumetric control by a robot, electronic inspection and artificial vision, riveting with a hydraulic press and assembly of components. Speed: 18 seconds/part.

-

Semiautomatic machine for clipping components

It enables several components to be clipped at the same time. Composed of 57 rubberized push pieces with individual pneumatic regulation. Speed: 20 seconds plus manual loading and unloading by an operator.

-

Semiautomatic ultrasonic welding machine

Ultrasonic assembly and welding station with analog monitoring via four points for each deflector (right and left). Speed: 35 seconds/part.

-

Bumper punching machine

This enables punching of housings for parking sensors as well as the rear camera, headlight washer, license plate and the corresponding adhesive coating or ultrasonic welding of the parking sensor support. Manual loading and unloading operation. Dies activated by controlled servos as well as pneumatically and hydraulically. Speed: 1 part/min.