Medical Automation

Inhalers, sprays, dialysis products, syringes, diagnostic products, suture kits... teknics specialises in assembly and functional control systems for the healthcare industry. We have more than 20 years of experience in this sector.

Our customers all over the world value our flexible automation systems, which are exclusively oriented to their production processes. A tailor-made project for every requirement is the hallmark of teknics, which is why our customers worldwide rely on us.

Benefits

Customers from all over the world value the technical advantages of our production and test systems.

Detailed planning, industrial know-how, advanced technology, customized service: We offer highly flexible production systems for the assembly and monitoring of your products.

Turnkey solutions and customized machinery

Our customers’ requirements and needs are the starting point of our activity.

Once the technical requirements and the needs to be met have been analyzed, our team proposes the best solution, incorporating the latest technologies available on the market.

Cost-effectiveness and customization

The teknics production systems bring cost reduction for customers thanks to automation and optimization of processes.

The monitoring and verification solutions implemented in our machines, eliminate costs arising from a lack of quality.

Delivery reliability

In a sector where time to market gets shorter every day, teknics guarantees a speedy response and reliability in all processes.

Accuracy, trustworthiness and professionalism are characteristic features of our teams, which are focused on fulfilling the delivery times agreed with the customer.

Total quality commitment

Our highly qualified teams and the quality of our solutions mean that teknics can implement projects throughout the world. We guarantee the same compliance standards in Europe, Asia, Africa and America.

We make sure that every operation and collaboration with our suppliers complies with the same strict quality requirements.

No matter where you are, we provide reliable processes and proven systems to guarantee that your production system works from day one.

Assembly and testing

Integration of the latest applied technologies in production systems and quality testing.

Experts in products

teknics need to know your product. Together with our customers we carry out exhaustive feasibility studies of the future automation, anticipating contingencies and reducing the impact on production costs and timing.

Experts in processes

teknics has carried out more than 1,200 installations since 1992.

This experience is what helps us provide something more than a solution to a customer’s needs, offering a general vision of the project in a comprehensive way.

Assembly

In collaboration with our customers we choose the best production solutions and the right type of automation of each process: FMS lines, rotary machines, semiautomatic machines, robotic stations, etc.

For every project we select the solution based on our experience and the technological developments generated by our innovation department.

Testing

At teknics, we are committed to technological innovation, incessantly seeking excellence in our testing solutions.

Each automation process requires different levels of control: traceability via CB or Data Matrix marking, RFID, automatic testing systems, serialization, OPC platforms, etc.

Each product requires different quality controls that guarantee our customers’ safety: from poka-yoke systems to advanced artificial vision monitoring systems, leakage checks, electronic functionality monitoring, calibration, etc.

Our aim is to provide control systems that is adapted to each process and each product, guaranteeing safety and better product quality for our customers.

Types

Turnkey and standard types of teknics machinery.

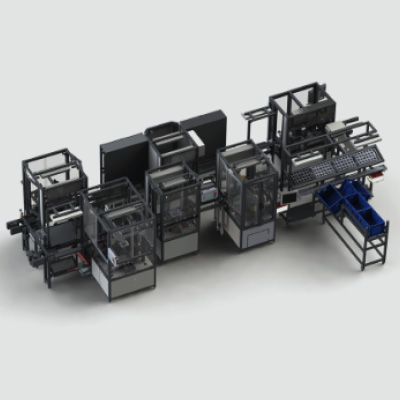

FMS: flexible

manufacturing system

Our FMS lines enable automation of production that varies a lot in terms of volumes as well as in terms of large number of product types and product characteristics.

These lines enable manual and automatic operations to be combined along the line, providing greater work flexibility. Furthermore, this type of line allows adaptation to our customers’ investment capacities, making it possible for the process to be automated gradually.

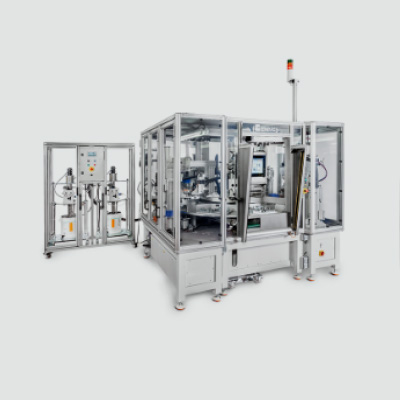

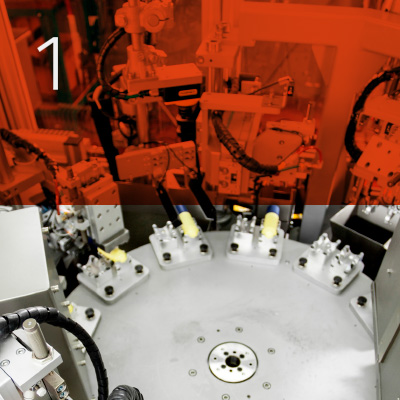

Rotary

machines

Rotary machines made by teknics are designed for automation of manufacturing of small products with a great variety of models.

The cycle time can be less than 1 second per part. Large volumes of production with very stable cycle times.

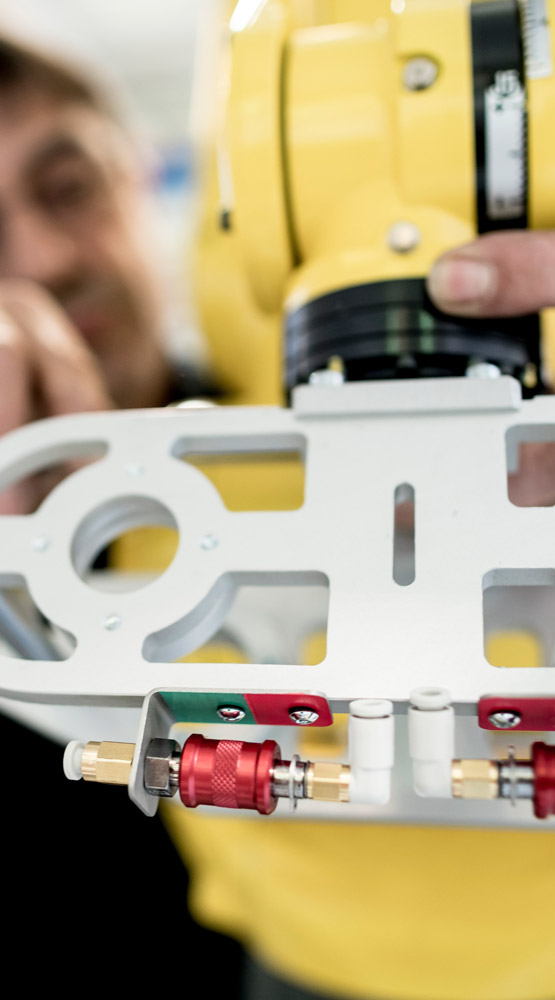

Robotic

stations

teknics designs component manipulation robotic cells allowing integration of production processes, including product testing and automatic case packing.

High level of flexibility allowing quick changes between formats and versions.

Related Projects

30 years and more than 1.200 projects carried out

-

Rotary machine for assembly and testing

Equipment consisting of a rotary plate with eight stations, enclosed within a cleanroom. The solution includes applications such as: vibration-driven feeding, component clipping, assembly, functional testing of the finished product and automatic unloading. Speed: 50 parts/min.

-

Automated station for loading onto assembly line

Automated station for loading onto assembly line. Automated station made up of a FlexPicker or a similar device for loading and unloading components (high speed). Equipment adapted to a cleanroom.

-

Automated station for loading onto a flow-pack line

Automated station for loading onto a flow-pack line. Automated station for loading products automatically on the flow-pack bucket feeder. Collection of the product by Scara robot. Multireference robot gripper adapted for each version. Speed: Varies between 60 and 100 parts/min (according to type).

-

Robotised station

Robotised station consisting of a delta robot for (highly flexible) loading and unloading of components. This solution includes applications such as: ultrasound sealing, laser generated 3D laser inspection. Frequency: 1500 parts/hour.