Projects

-

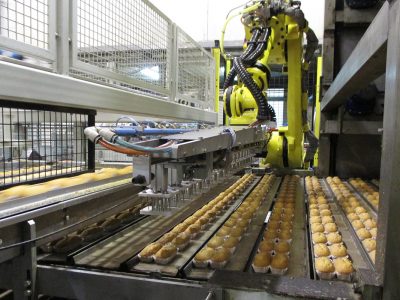

Robotized station loading onto flowpack line

Line that incorporates a robot for loading and unloading products (highly flexible) in flow pack for their later distribution and loading in multipack. Extendable gripper adapted to flow-pack pace. Rate: 280 packets/min.

-

Laser marking station

Lateral laser marking station for glass bottles on an FMS line. Detection of presence of alcohol residue in the bottles, a vapor extraction area. Speed: 30 parts/min.

-

Automatic palletizing

Robotic cell for the automatic palletizing of different box models. Rate: variable, depending on the box size.

-

Bumper punching machine

This enables punching of housings for parking sensors as well as the rear camera, headlight washer, license plate and the corresponding adhesive coating or ultrasonic welding of the parking sensor support. Manual loading and unloading operation. Dies activated by controlled servos as well as pneumatically and hydraulically. Speed: 1 part/min.

-

Inspection equipment

Equipment built into the production line itself for detecting contaminants in solution. It consists of four artificial vision cameras. Frequency: 52.000 units/hour.