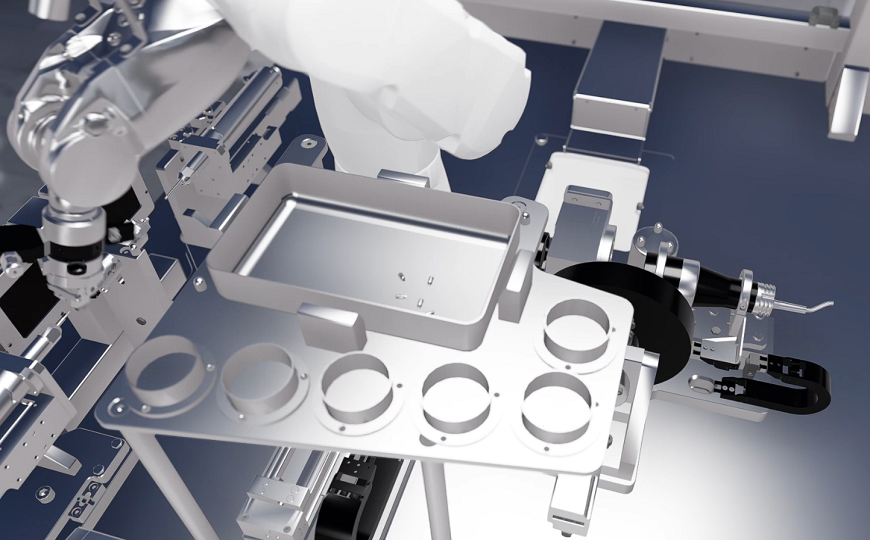

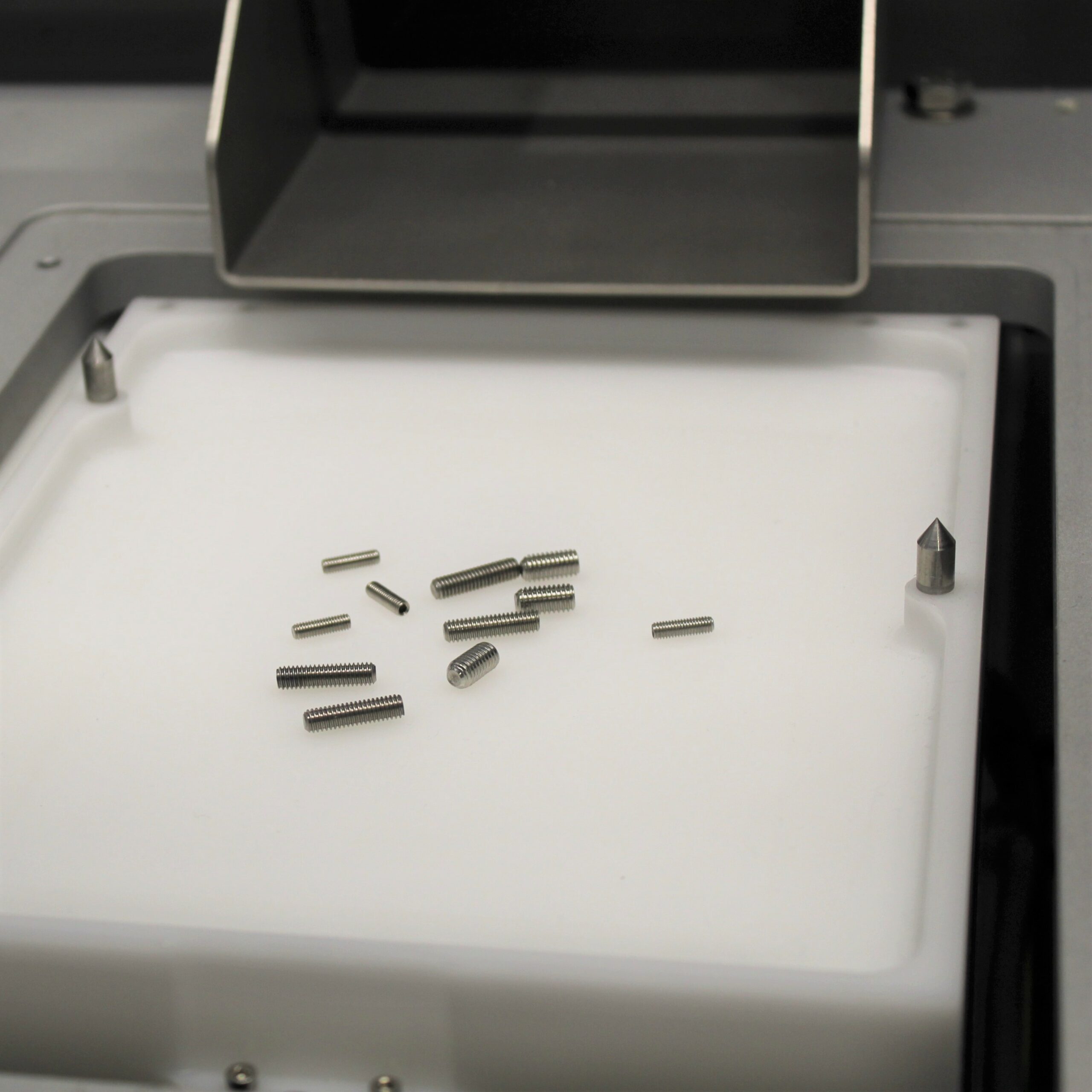

DentalTest in action, Dental Implant Quality Station

DentalTest DT100

Dental Implants Quality Station: System for monitoring dimensions, surface and marking

teknics has developed a flexible solution for monitoring Dental Implants and Abutments. A Dental Implant Quality Station, capable of performing high-precision dimensional control along with aesthetic defect analysis by implementing artificial vision technology and Deep Learning.

The equipment is configurable for multiple formats and allows the end user to directly add new references.

Its compact dimensions, combined with its high autonomy, enable seamless integration into the customer's production process.

Advantages

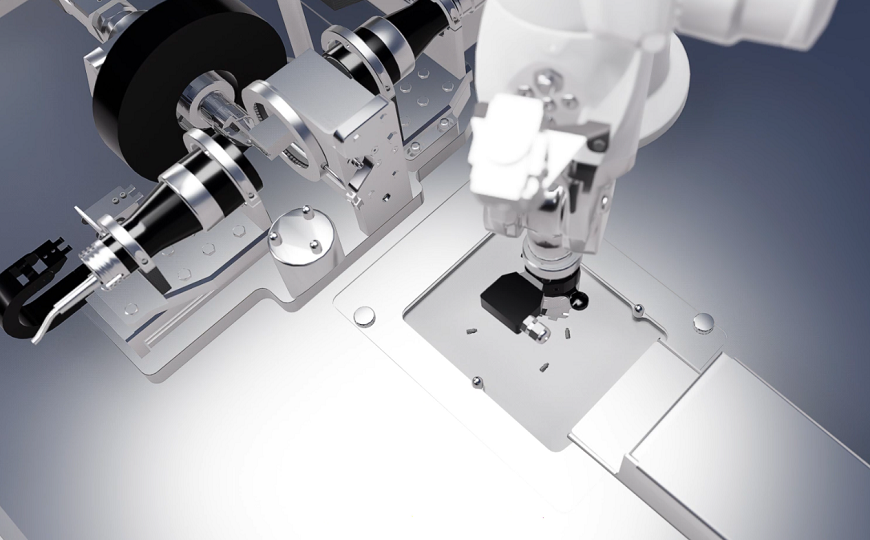

Maximum Flexibility

The flexible feeding system allows us to work with a wide variety of product families:

- Implants

- Pillars

- Epitoidials

- Scanbody

- Screws

- Analogues

- Transfers

- Others

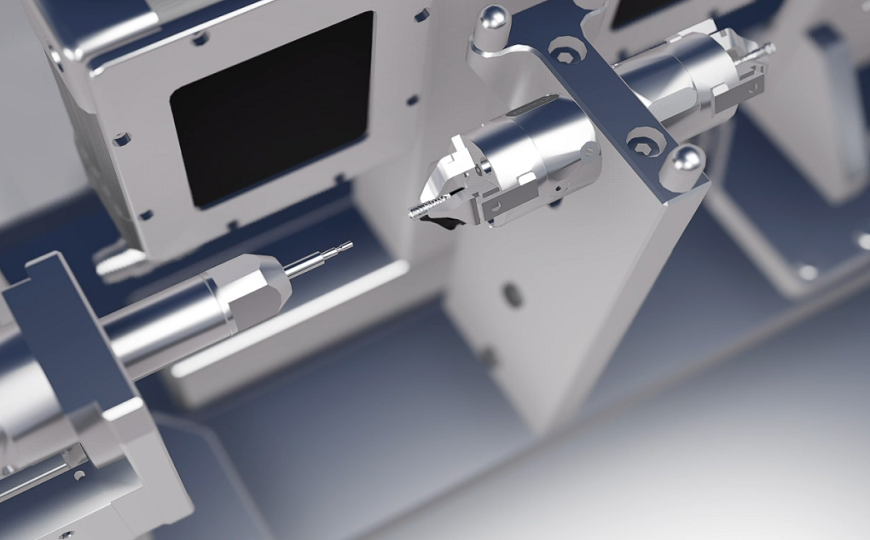

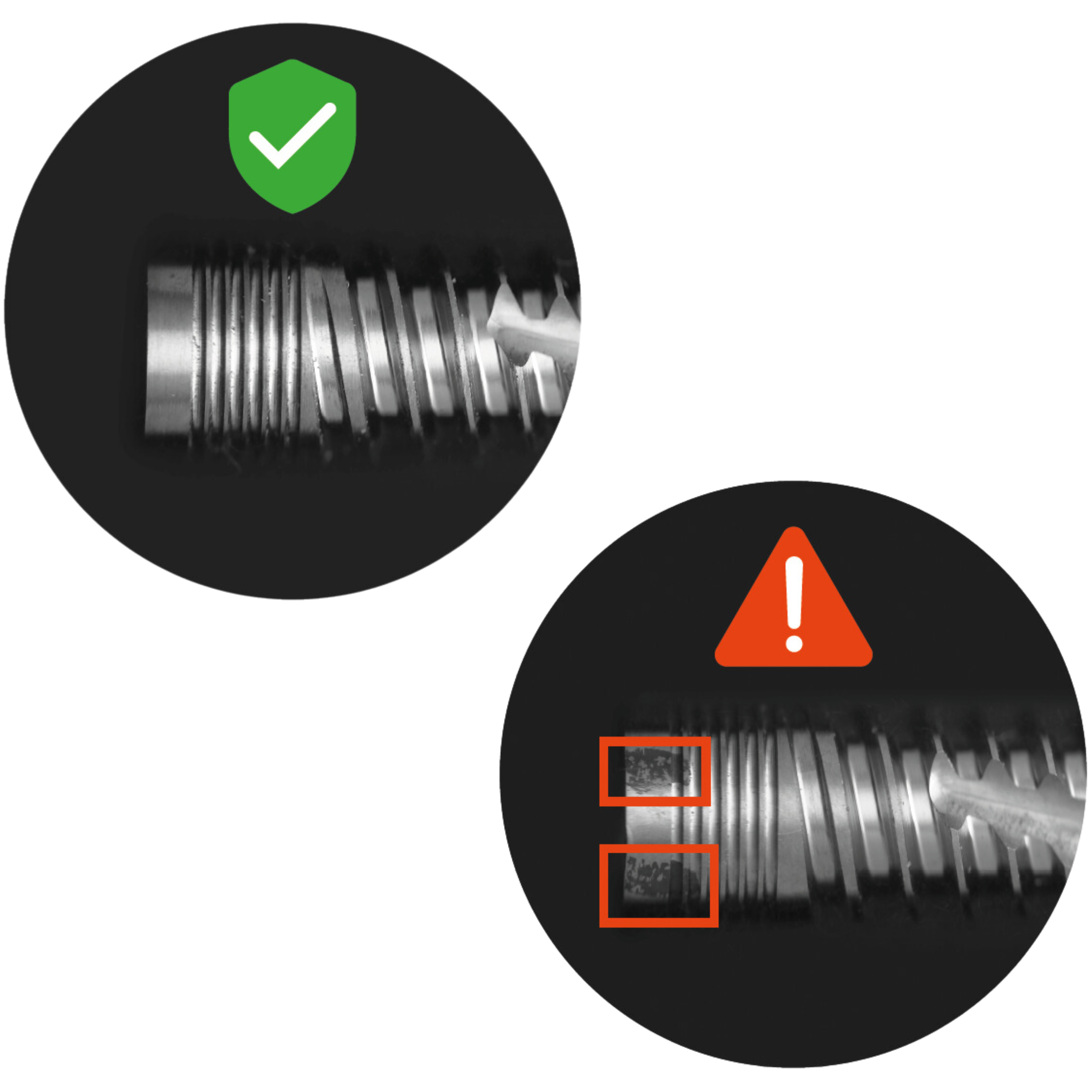

Surface Inspection

The system features Deep Learning technology, enabling the detection and inspection of surface defects based on customer-defined criteria.

Additionally, the machine has learning capabilities and continuous improvement, enhancing its robustness.

Types of defects that we can detect:

- Marks/Scratches/Dents

- Dirt/Burrs

- Non-homogeneouscolour/Wrong anodizing

- Others

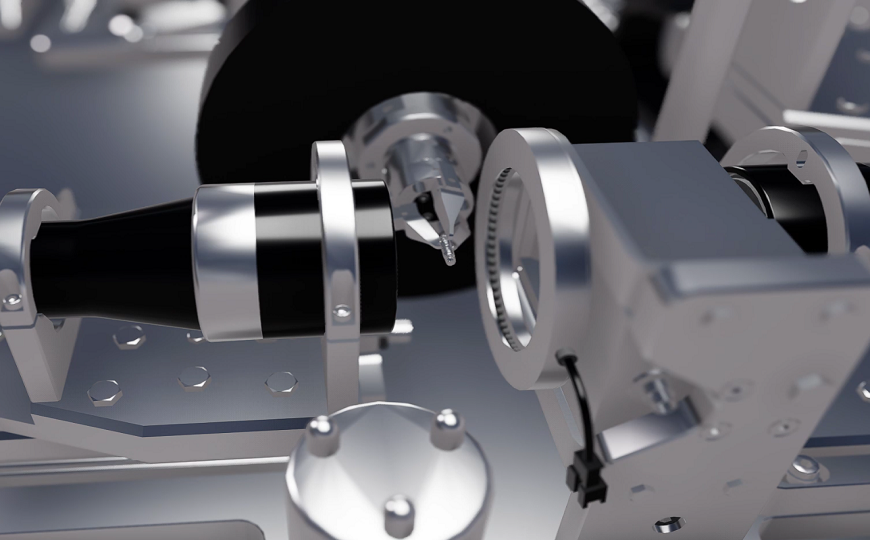

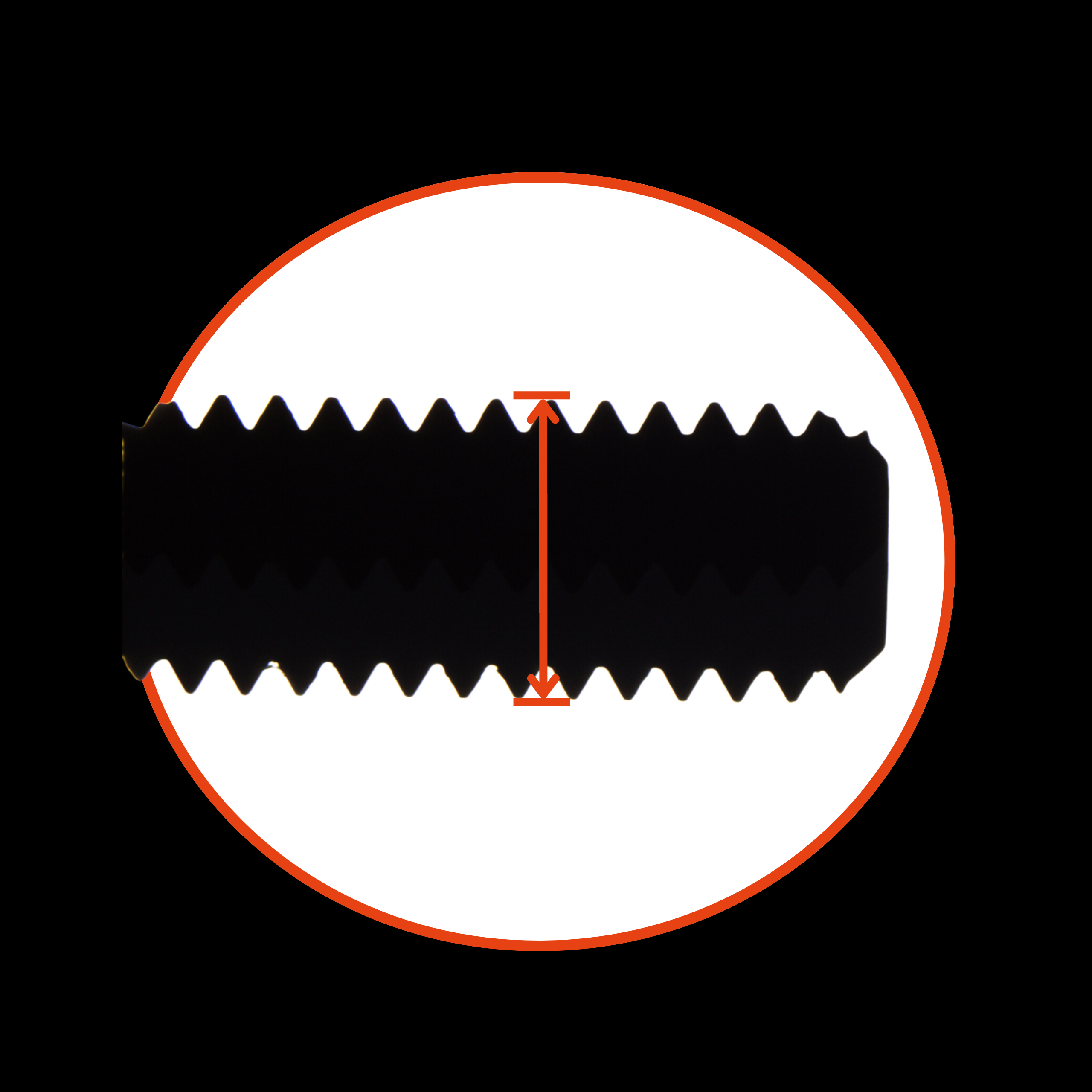

Dimensional Control

Through artificial vision or mechanical control of internal dimensions.

This system allows large number of mechanized coordinates to be supervised, recording any deflection from the corresponding error categories.

The viewing resolution is ±0.025 mm (with a Cmk of 1,67). For minor resolutions, a personalized study is carried out.

Deep Learning

Based on artificial intelligence for the identification of surface defects. The system is designed to allow the end user to train and configure the machine to learn new defects.

The more the machine is trained, the more robust it becomes, leading to increasingly precise quality control of dental implants.

A flexible solution for a constantly changing world