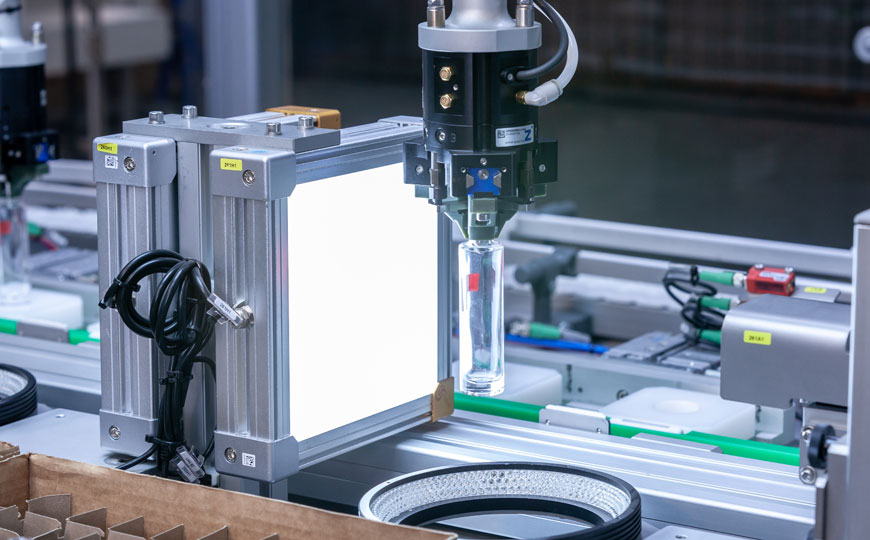

GlassFeeder in action, bottle feeding system

GlassFeeder GF100, GF200, GF300

Smart Glass Bottle Feeding System

The teknics team has developed the bottle feeding system called GlassFeeder, a modular equipment unit that can be easily integrated into our customers' production lines.

This system enables the automatic feeding of multiple bottle references through the advanced Deep Learning intelligence system.

The flexibility of this feeding system allows glass bottles to be handled independently of the input packaging.

Advantages

Maximum Flexibility

Allows us to work with a large number of glass bottle formats, with different geometries, dimensions, colours, chrome-plated surfaces and heights, providing total flexibility to our customers.

The intelligent tray feeding system adapts to different formats and sizes, whether they are cardboard, with separators, incorporated or thermoformed.

A good solution for other cosmetic-related products such as caps and accessories.

Fast Format Changes

Ideal for multi-reference lines for both large and small batches, where changes must be quick. This allows us to reduce downtime and therefore the final cost of the product.

Insert the New Formats Yourself

The bottle feeding system has Deep Learning technology that allows new references to be inserted quickly at the user level, reducing dependency on suppliers.

Modularity and Adaptability

teknics customises the GlassFeeder by adapting different modules to your needs, either by the desired rate and autonomy, such as the incorporation of the laser marking system or a system for loading and unloading trays from pallets with a cobot.

A flexible solution for a constantly changing world

Send us your query and we will help you make your project come to life.

Thank you very much