Projects

-

Robotic cell for glass bottle laser marking

Robotic cell for laser marking of text required by legislation on the base of glass bottles. Speed: 40 units/min

-

Automatic assembly line for bottle tops

Line consisting of automatic storage for trays of bottle tops for their subsequent assembly on bottles by robots or manipulators. Speed: 45 units/min

-

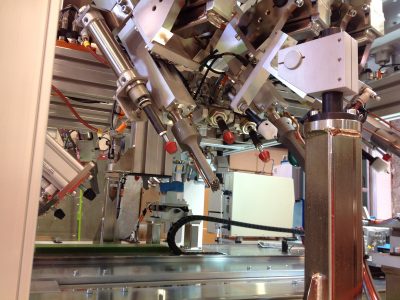

Automatic line for assembling packages and checking contents in the packaging

Assembly line for the final packaging made up of a bottle, a corresponding base and a metal can. High level of flexibility that enables the assembly of all sizes of products and checking of the correct positioning and presence of all components. Speed: 20 to 50 units/min (according to model).

-

Rotary machine for assembly and testing

Equipment consisting of a rotary plate with eight stations, enclosed within a cleanroom. The solution includes applications such as: vibration-driven feeding, component clipping, assembly, functional testing of the finished product and automatic unloading. Speed: 50 parts/min.

-

Automated station for loading onto assembly line

Automated station for loading onto assembly line. Automated station made up of a FlexPicker or a similar device for loading and unloading components (high speed). Equipment adapted to a cleanroom.

-

Flexible feeding system with laser marking

Consisting of two synchronised robotic stations for artificial vision-guided loading and unloading of components. Station for laser marking and inspection of the engraved product. Speed: 4 seconds/part.

-

Rotary machine for assembling components

Rotary station with eight positions. This station includes applications such as: silicone dosing with volumetric control by a robot, electronic inspection and artificial vision, riveting with a hydraulic press and assembly of components. Speed: 18 seconds/part.

-

Semiautomatic machine for clipping components

It enables several components to be clipped at the same time. Composed of 57 rubberized push pieces with individual pneumatic regulation. Speed: 20 seconds plus manual loading and unloading by an operator.

-

Automated station for loading onto a flow-pack line

Automated station for loading onto a flow-pack line. Automated station for loading products automatically on the flow-pack bucket feeder. Collection of the product by Scara robot. Multireference robot gripper adapted for each version. Speed: Varies between 60 and 100 parts/min (according to type).

-

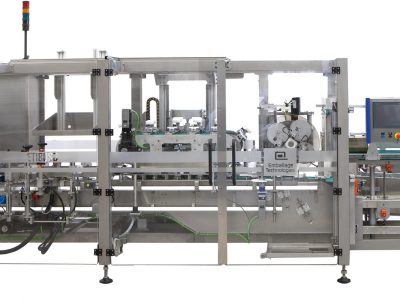

Cartoner with automatic horizontal loading

Totally flexible, high-velocity machine. Adhesive system using hot-melt adhesive, with automatic switching. Carton dimensions: – Length: 75 a 320 mm – Width: 30-180 mm – Height: 16 to 100 mm Frequency: Up to 220 cartons/minute

-

Semiautomatic ultrasonic welding machine

Ultrasonic assembly and welding station with analog monitoring via four points for each deflector (right and left). Speed: 35 seconds/part.

-

Robotised station

Robotised station consisting of a delta robot for (highly flexible) loading and unloading of components. This solution includes applications such as: ultrasound sealing, laser generated 3D laser inspection. Frequency: 1500 parts/hour.